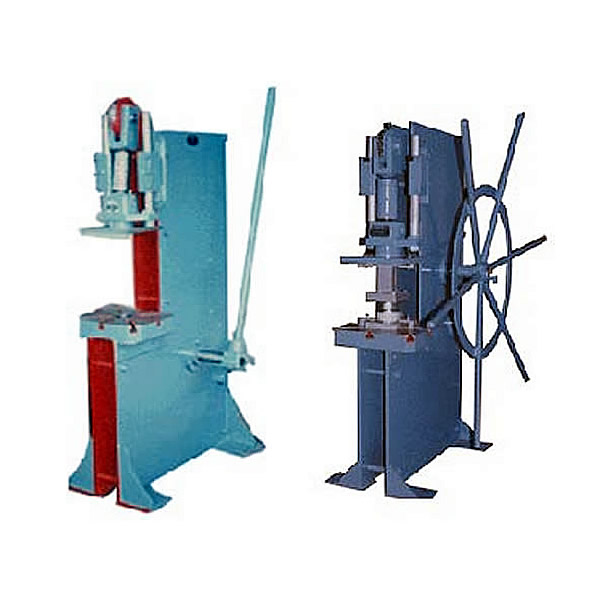

Model PRESSMAN Ram-Type Hydraulic Compression Moulding Machine

FEATURES:-

- Heavy steel fabricated body of l-beam and plate construction.

- Graded cast-iron platens of liberal thickness.

- Uniquely designed telescopic main press cylinder. The cylinder is openable at both ends for in-situ-servicing. The use of telescopic cylinder results in the fast and accurate operation of the press with mould beginning to close at fast speed, and low pressure. Slow mould closing at full pressure can be selected to develop desired pressure just before the mould is fully closed. This not only provides safety to the mould but also results in substantial power savings.

- The top platen approach and return are at dual speed.

- Variable breathing cycle at intermediate pressure before final curing pressure is possible to degas the mouldings.

- Top and bottom ejecting systems are provided.

- A slow opening feature is provided to prevent mouldings from breaking due to jerks during the opening.

- Electrical and hydraulic controls are in-built with the press and integrated to provide flexibility of working.

- Safety gate is fitted to reverse the machine, if opened during pressing period.

- Heating points are provided for both platens and controlled by electronic temperature controllers.

- Transfer moulding facility can be provided, extra. Standard machine is suitable for compression moulding.

-

MACHINE CAPACITY DOWNSTROKES 30 tons 60 tons 100 tons 150 tons 250 tons

Click on image to download PDF